Pre Purchase Inspection

A pre-purchase inspection (PPI) for an aircraft is a comprehensive evaluation conducted before finalizing a sale to assess its condition, identify potential issues, and ensure it meets the buyer's expectations. The workscope of a PPI typically includes a thorough review of aircraft records, a physical inspection of the airframe, engines, and systems, and potentially a test flight. It also involves evaluating the aircraft's maintenance history, identifying any damage or wear, and assessing its overall airworthiness and value. We understand the significant role of PPI to protect your company from a loss in acquiring an Aircraft. We can provide such service to bring you into satisfaction

:

The works that we can do, shall be as follow:

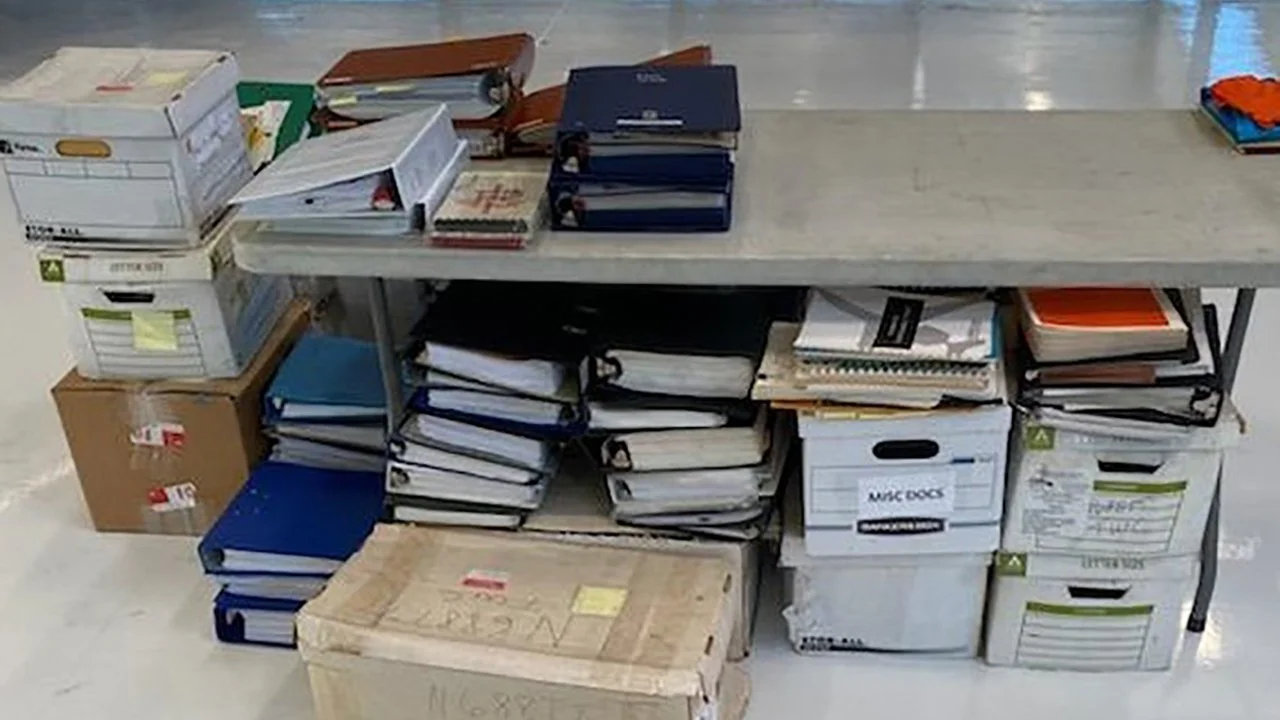

1. Records and Documentation Review:

Logbooks: Reviewing maintenance logs, inspection records, and modification paperwork to verify compliance with regulations, ensure accurate maintenance history, and identify any discrepancies or missing records.

Airworthiness Directives (ADs) and Service Bulletins (SBs): Verifying that all applicable ADs and SBs have been complied with.

Modifications and STCs: Assessing any modifications or Supplemental Type Certificates (STCs) to ensure they are properly documented and approved.

2. Physical Inspection

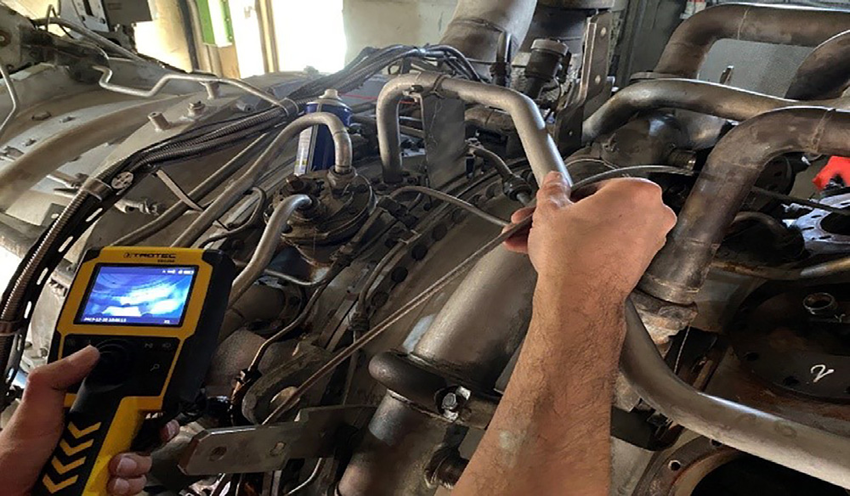

3. Borescope Inspection (upon request / if necessary)

1. Borescopes allow for visual inspection of internal engine components without disassembly, saving time and resources. Help identifying early signs of wear, corrosion, cracking, or damage, which could escalate into major problems if not addressed.

2. By examining critical areas like turbine blades and combustion chambers, borescopes provide valuable insights into the engine's overall condition.

3. Buyers can use the information from borescope inspections to make informed decisions about the purchase price, potential maintenance needs, and whether to proceed with the acquisition.

4. Borescope inspections help protect the aircraft's value by identifying and addressing potential issues early on, preventing costly repairs down the line. The findings can be used as leverage during price negotiations with the seller, potentially saving the buyer money.

Airframe: Examining the structure for damage, corrosion, and previous repairs.

Engines: Assessing engine condition through compression checks, oil analysis, and potentially borescope inspections.

Avionics and Electrical Systems: Testing flight instruments, radios, navigation systems, and other onboard electronics.

Landing Gear: Checking for wear on tires, brakes, and hydraulic systems.

Fuel System: Inspecting for leaks and contamination.

Cabin and Interior: Evaluating the condition of seats, seatbelts, oxygen systems, and other safety features.

Control Surfaces: Inspecting wings, rudders, and elevators for damage and proper operation.

Exterior: Checking for damage, deformations, and other visible issues.